The main goal of the Pcb Inspection Course is to offer students with the perfect inspection strategy to help review the product physically. The main goal is to determine whether or not the product will match the IPC-A-610 guidelines.

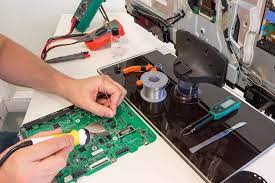

Here, the students get the opportunity to learn ways to find the problematic areas on assemblies. Their primary focus will be on improving product yields. Students get the chance to learn how to improve discrimination and their inspection skills under trained professionals. This course is mainly intended for personnel inspecting PCB assemblies. Even an employee can take an active part in here, who is otherwise associated with vendor qualification.

More about the course modules:

This particular PCB-based inspection course is allotted for one day only, and there will be practical hands-on sessions too. The discussion is crafted on the skills learned in the IPC-A-610 sector. Here, it is important for the attendees to have prior knowledge of the inspection requirements, as mentioned in the IPC-A-610 document. It is important to be familiar with Module 1 of the IPC-A-610 certification if you want to proceed with this course module.

The topics included in the list:

Now before you enroll your name in this PCB inspection course module, learning about the topics is important. Some of the major ones are listed below:

- XRAY inspection-transmissive

- BGA inspection

- Wire and terminal inspection

- Magnification and lighting

- Visual Inspection Strategies

- Leadless device inspection

- SMT inspection

- Through-hole inspection, and

- Handling Electronic Assemblies

Each course module will be thoroughly discussed by our team of well-trained experts. They will first get to the basics of the course and then slowly move into the deep sector of the same topic. In the end, after completion of the course module, you will receive satisfaction and gain better knowledge as well.

Tips you learn in the PCB inspection course:

PCBs form a major part of electronic devices. This plays a major role and will have a huge impact on the entire product. You need IPC-A-610 for determining the PCB quality, so it is better to meet the specifications beforehand. The most common PCB inspection is to look for some irregularities in the board’s thickness. If you are not sure how thick it might be, then compare it with a sample or any existing one. Check out if there are any bends on the surface. Even the panel needs to be free from any kind of cracks to ensure better quality. For checking and selecting the best PCB for your application, being part of the inspection course is mandatory.

On the other hand, you need to check if two or more pads can be combined because of extra solder applications, also called Solder Bridging.

Determining the overall performance level:

Printed circuit boards are crucial components in any of the electronic devices, which will determine the overall performance of the mechanism. Therefore, it is vital to check whether or not it should match the quality standards as mentioned in IPC A 610.

Are you aware of the steps of designing, manufacturing, and assembling procedures? If you fail to do so, then you will remain uninformed about the PCB strategy. That’s when the inspection course comes to the rescue.

Starting off with the board inspection:

The common way for inspecting PCBs is by checking whether the thickness of the board is right or not. Also, you have to check whether the surface is bent, rough, or twisted right out of shape.

Now for the conductive pattern:

The very next thing is to check whether these conductive pathways are consistent and clear or not. Other than that, through these inspection courses, you will come to check if two pads or more are connected because of the extra solder application. If so, it is called “solder bridging.”

Getting along with the dimension check:

Make sure to take time and learn how to check the dimensions of assembly. You can do that by matching it with the specifications as mentioned in IPC A 610. You will also be trained to grow an eye for details while checking the electric connectors’ dimensions.

Checking the quality of surface region:

For covering this stage, you need the power of a magnification device. It helps you to check the quality of the surface of PCBs. You have to watch carefully for the scratches, dents, or even pinholes on the surface of these circuit boards, which will affect the quality of the board even more.

Checking out the pad plating:

Plating is a thin coat of materials like copper, gold, or silver. So, make sure to check that plating on the pad and see if that remains rough, bright, or firm. There should not be any bulging effect on board too.

You will learn these tricks and tips of PCB inspection once you have come across the best team for the course modules.

FS TECH was established in 2004 and is located in Shenzhen, GuangDong. As an Electronics manufacturing services contract manufacturer, FS Tech specializes in PCB fabrication, pcb component procurement, PCB Assembly, testing and quality control as well as finished products assembly services.